Magnetic levitation motor

零售价

市场价

重量

库存

隐藏域元素占位

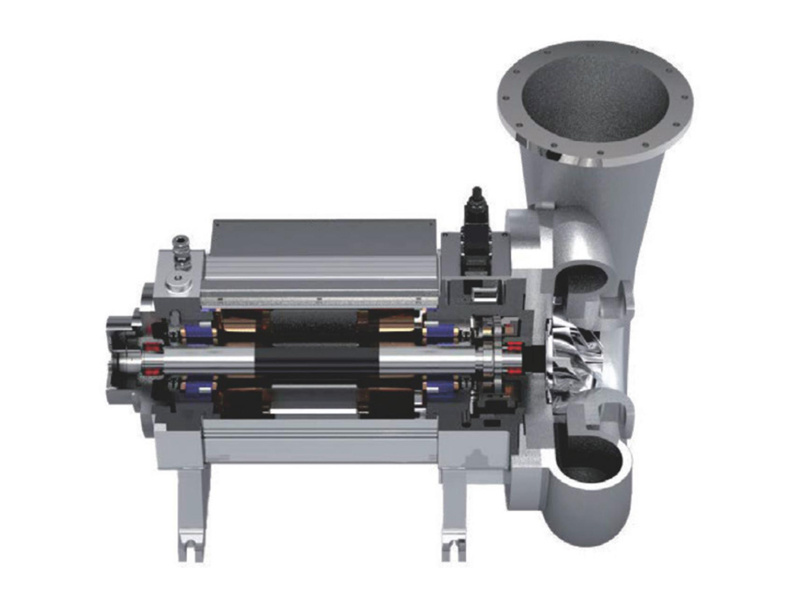

Magnetic levitation motor

Magnetic levitation motor is a new generation of “digital and electric” fusion of high-speed motor products. Through real-time detection of displacement of rotating shaft by built-in displacement sensor, the collected signals are sent to the magnetic levitation bearing controller for modulation and calculation to generate control current, and then the current is input to the magnetic bearing coil to generate electromagnetic force, so as to realize the suspension of the motor rotor. At the same time, the frequency controllable current is generated by the frequency converter, and the current is input to the motor stator to generate a rotating magnetic field, which drives the rotating shaft to rotate at high speed, thus realizing the “no mechanical friction” operation and breaking through the limitation of the mechanical bearing on the motor speed due to friction loss and vibration.

Category:

Products & Services

- Description

-

Solution of customized medium and high power high speed turbine machinery

Magnetic levitation motor is a new generation of “digital and electric” fusion of high-speed motor products. Through real-time detection of displacement of rotating shaft by built-in displacement sensor, the collected signals are sent to the magnetic levitation bearing controller for modulation and calculation to generate control current, and then the current is input to the magnetic bearing coil to generate electromagnetic force, so as to realize the suspension of the motor rotor. At the same time, the frequency controllable current is generated by the frequency converter, and the current is input to the motor stator to generate a rotating magnetic field, which drives the rotating shaft to rotate at high speed, thus realizing the “no mechanical friction” operation and breaking through the limitation of the mechanical bearing on the motor speed due to friction loss and vibration.

High power and high speed permanent magnet synchronous motor

High power density, small volume and light weight.

Design of passive and safe cooling internal circulation.

Anti-loss-of-excitation design in whole life cycle.

Compound rotor with higher reliability.

The actual operating efficiency of the motor exceeds 97%.

Three-dimensional fluid impeller with high efficiency

Wide adjustment range of air volume operation and surge resistance.

Directional optimization based on practice, with high efficiency.

Redundant strength design, and safer operation.

Integrated processing and molding, excellent product consistency.

Aviation aluminum, titanium alloy, and better material matching scheme.

Five-degree-of-freedom magnetic levitation bearing system

Control technology of active compensation for unbalance.

Patent structure of “three highs and one low”.

High protection design (integrated full package).

High load-bearing design (strong impact resistance).

High voltage and low inductance design (fast dynamic response).

Intelligent control system

Self-developed SMART operating system.

Self-adjustment according to working conditions for better operation matching.

Local and remote dual control and dual diagnosis.

Monitoring of key parameters and automatic protection of danger signals.

Customizable control interface, and humanized operation logic.Core component

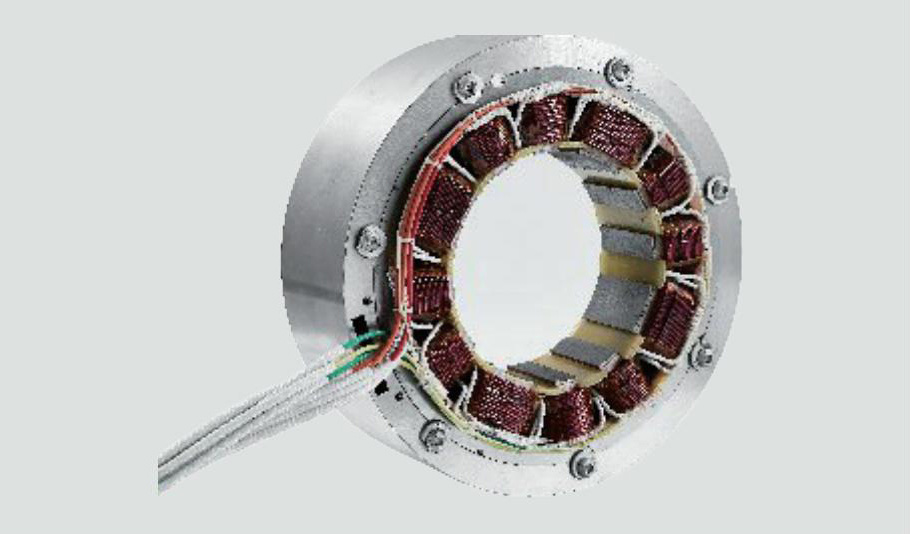

Rotor of high speed motor

Magnetic levitation bearing

Magnetic levitation bearing controller

Centrifugal impeller

Selection table of magnetic levitation motor products

Customized application platform of magnetic levitation motor

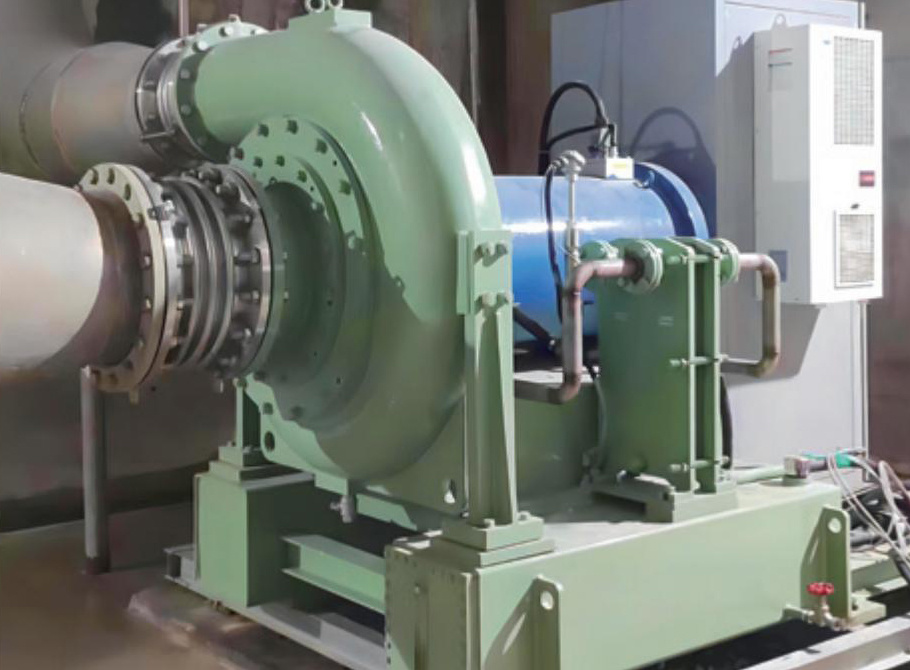

Core machine of magnetic levitation blower

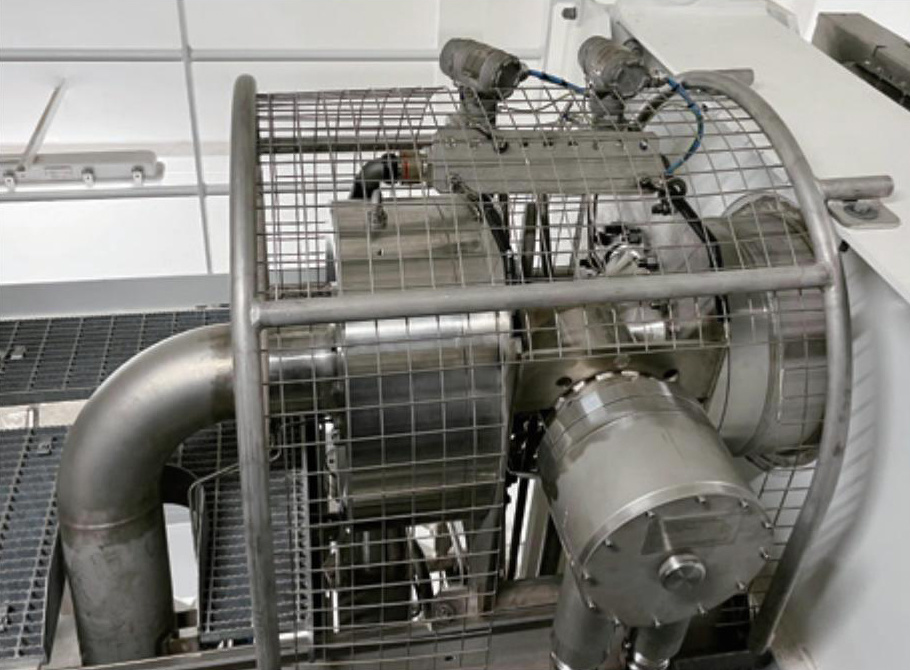

Core machine of magnetic levitation air compressor

Magnetic levitation vacuum pump

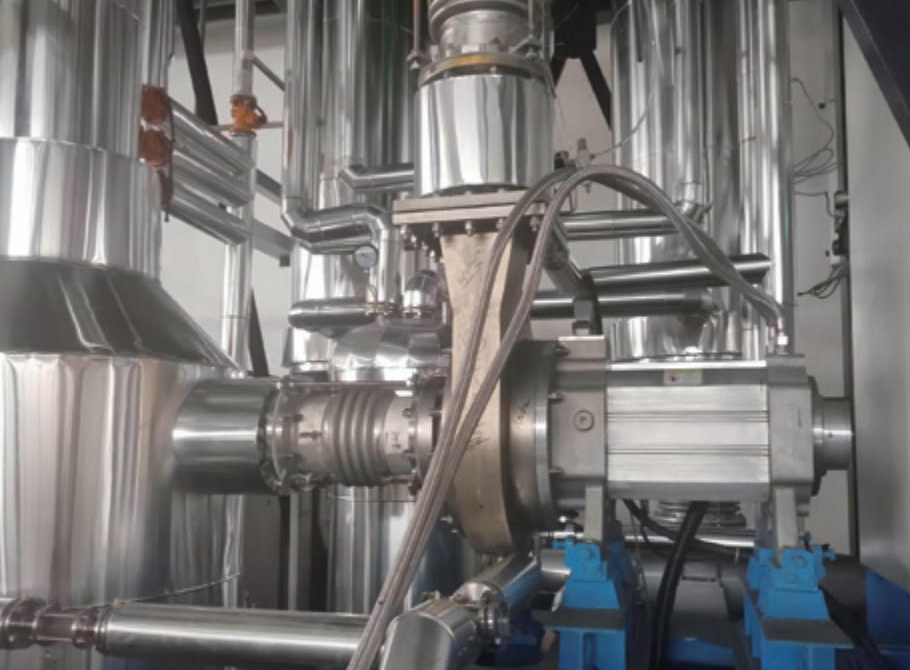

MVR steam compressor

ORC waste heat generator

Magnetic levitation expansion compressor

Process gas conveying fan

Special high pressure compressor