"Farhills" series magnetic levitation air compressor

零售价

市场价

Industrial manufacturing: Cement manufacturing, chemical plant, hydropower plant, food industry, foundry, etc.

Control instruments: Machine tools, printing machinery, power plant auxiliary equipment control, train brake gate, track lane change device, control valve, instrument power, etc.

Surface spraying and purging: Metal surface sandblasting, surface painting, power plant pipeline cleaning, smelter, dust purging, workbench cleaning, etc.

重量

库存

隐藏域元素占位

"Farhills" series magnetic levitation air compressor

Blowing and inflating: Blow molding, pipe blowing, bottle blowing, food filling, elastic addition in textile industry, etc.

Industrial manufacturing: Cement manufacturing, chemical plant, hydropower plant, food industry, foundry, etc.

Control instruments: Machine tools, printing machinery, power plant auxiliary equipment control, train brake gate, track lane change device, control valve, instrument power, etc.

Surface spraying and purging: Metal surface sandblasting, surface painting, power plant pipeline cleaning, smelter, dust purging, workbench cleaning, etc.

Category:

Products & Services

- Description

-

Solution of applying magnetic levitation air compressor

The platform-based core machine scheme helps the air compressor enter the era of efficiency, energy saving and oil-free

100% oil-free

The high-speed motor adopts magnetic levitation bearing, the whole system has no other mechanical transmission structure, does not need to use lubricating oil, and is easy to maintain, and the compressed air reaches ISO8573-1 Class 0

No performance attenuation

With the application of magnetic levitation bearing technology, the whole system of magnetic levitation air compressor has no other mechanical transmission structure, and compared with the traditional oil-free air compressor, the performance will not be attenuated in the whole life cycle

Low energy consumption

With three-dimensional fluid impeller two-stage compression + intermediate cooling + system fluency analysis technology, the transmission efficiency of magnetic levitation air compressor is close to 100%, and compared with traditional oil-free air compressor, the energy saving is about 20%

Low operating noise

Magnetic levitation air compressor adopts circuitous cabinet inlet and low resistance fluid noise reduction design, and the noise value is lower than 80 dB

Multilevel protection

Magnetic levitation air compressor adopts multiple protections such as “active vibration isolation + uninterruptible power supply + mechanical protection bearing + self-generating protection” to prevent equipment from accidental shutdown and damage due to external interference

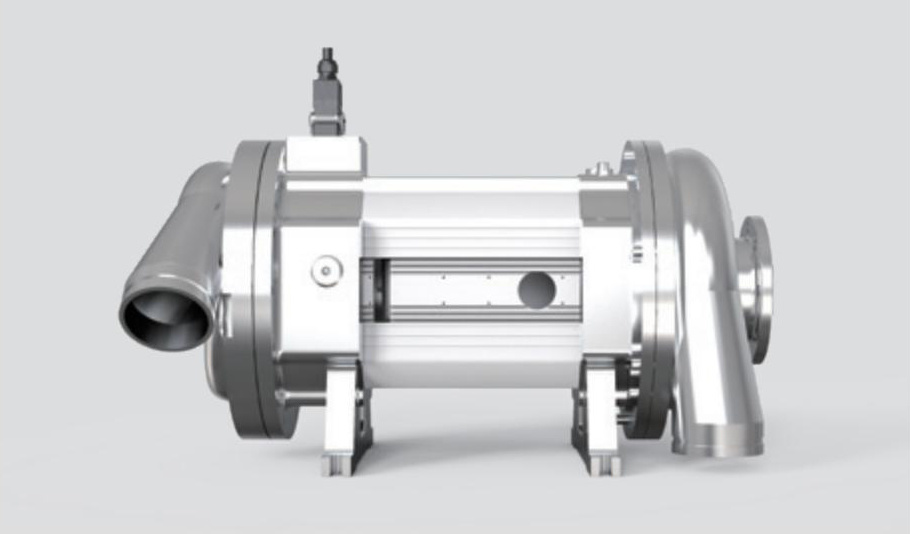

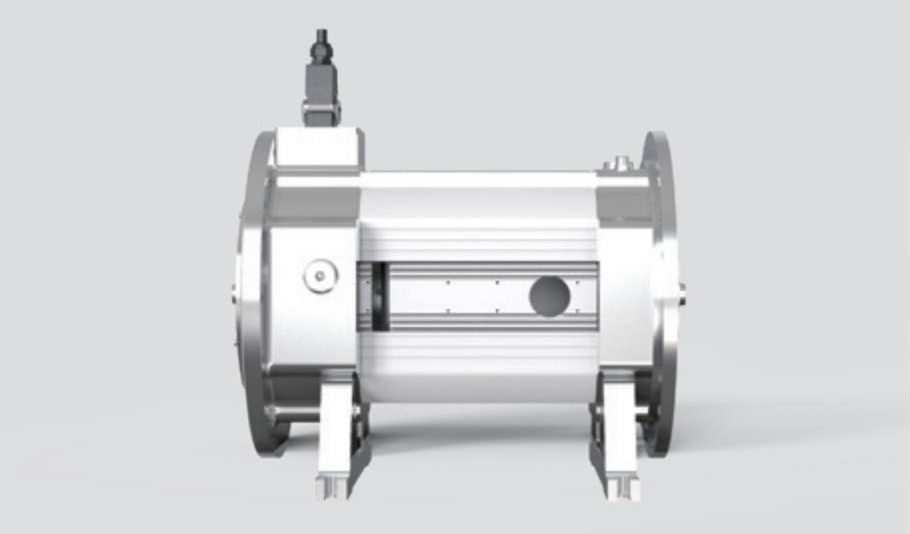

Core component

Two-stage compression core machine

Passive safety high-speed motor

Low noise control technology of air compressor

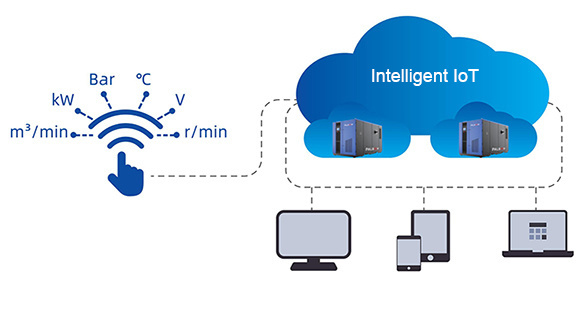

Intelligent control system of air compressor

Selection table of air compressor products

Application area

Blowing and inflating: Blow molding, pipe blowing, bottle blowing, food filling, elastic addition in textile industry, etc.

Industrial manufacturing: Cement manufacturing, chemical plant, hydropower plant, food industry, foundry, etc.

Control instruments: Machine tools, printing machinery, power plant auxiliary equipment control, train brake gate, track lane change device, control valve, instrument power, etc.

Surface spraying and purging: Metal surface sandblasting, surface painting, power plant pipeline cleaning, smelter, dust purging, workbench cleaning, etc.