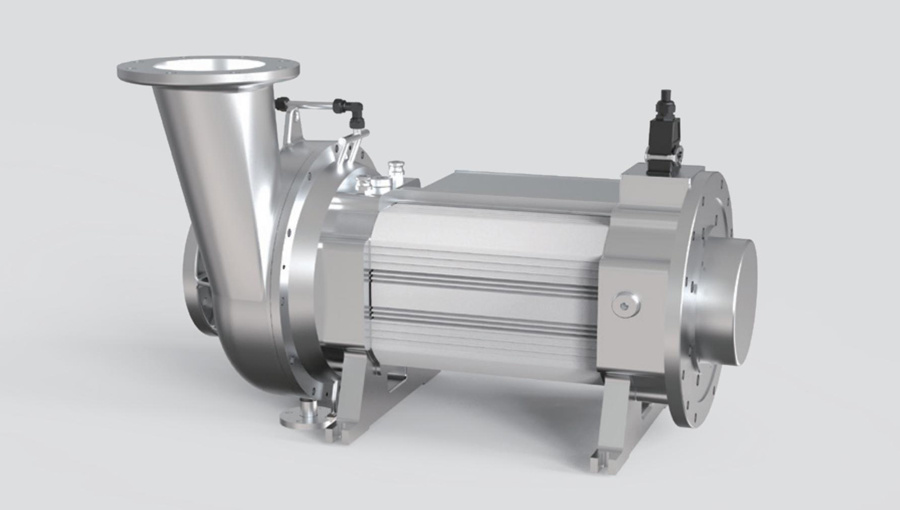

Magnetic levitation compressor

零售价

市场价

Food fermentation industry: Amino acid concentration and extraction, sugar solution concentration and drying, beverage jam concentration and so on

Pharmaceutical industry: Evaporation, concentration, crystallization and drying in the production process of Chinese and Western medicines

Others: Coal mine wastewater treatment, Salt Lake lithium extraction, seawater desalination and so on

重量

库存

隐藏域元素占位

Magnetic levitation compressor

Energy conservation and environmental protection industry: Industrial wastewater concentration, wastewater recycling, landfill leachate treatment, etc.

Food fermentation industry: Amino acid concentration and extraction, sugar solution concentration and drying, beverage jam concentration and so on

Pharmaceutical industry: Evaporation, concentration, crystallization and drying in the production process of Chinese and Western medicines

Others: Coal mine wastewater treatment, Salt Lake lithium extraction, seawater desalination and so on

Category:

Products & Services

- Description

-

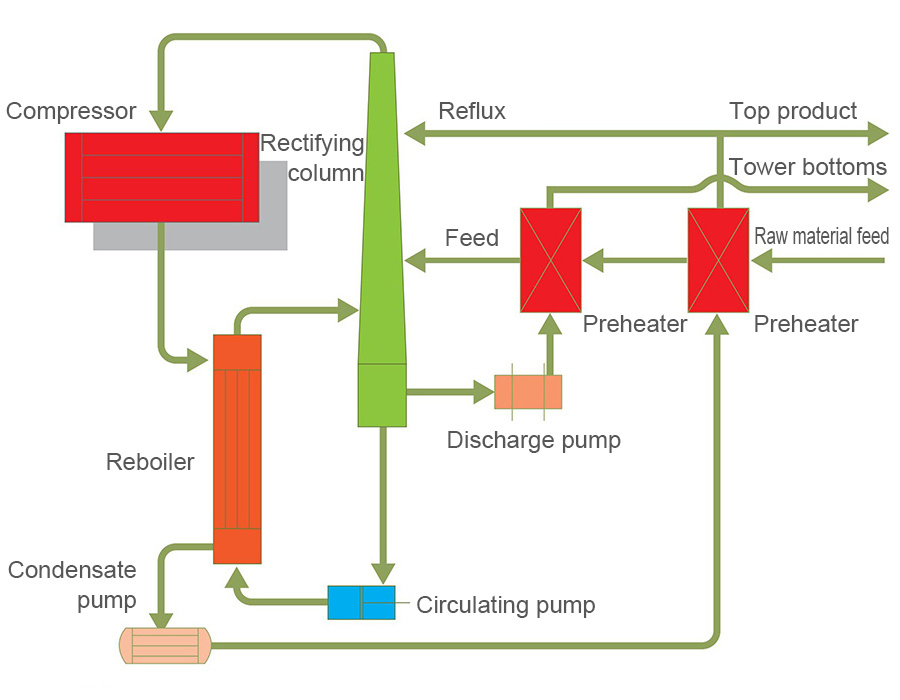

Solution of applying magnetic levitation compressor in MVR

Energy saving and environmental protection, excellent machine to realize zero discharge of industrial wastewater

MVR is an energy-saving technology that reuses the secondary steam energy generated by the evaporation system itself and reduces the demand for external energy. Its principle is to compress the secondary steam from the evaporator through a high-energy-efficient steam compressor, convert electric energy into heat energy, and improve the pressure and temperature of the secondary steam. After heating up, the secondary steam returns to the evaporator to heat the materials and generate evaporation, thus achieving the purpose of recycling the latent heat of secondary steam vaporization.

The product is suitable for the working conditions of flow range of 1-10 t/h and temperature rise of 8-22℃.

Efficiency and energy saving

The high-speed magnetic levitation motor is directly coupled with the three-dimensional fluid impeller, and the efficiency is improved by 25%-30% compared with the traditional compressor

Intelligent control

PLC + 4G technology is adopted to access the system status in real time through central control and mobile terminals, thus realizing “full life cycle management”

Accurate sealing

The dynamic seal technology of “axial labyrinth seal + radial carbon ring seal” and patented structure is adopted, which is safe and reliable

Low noise

The high-speed motor is supported by magnetic levitation bearings, without any mechanical contact and friction during rotation, with low vibration and low noise

Maintenance-free

Magnetic levitation bearing, with no mechanical contact, no friction, and no lubrication system. The equipment is provided with a skid-mounted structure, which is convenient to install

Product platform

500 kW MVR special magnetic levitation motor platform

Customized MVR magnetic levitation core machine platform

Selection table of MVR products

Application area

Energy conservation and environmental protection industry: Industrial wastewater concentration, wastewater recycling, landfill leachate treatment, etc.

Food fermentation industry: Amino acid concentration and extraction, sugar solution concentration and drying, beverage jam concentration and so on

Pharmaceutical industry: Evaporation, concentration, crystallization and drying in the production process of Chinese and Western medicines

Others: Coal mine wastewater treatment, Salt Lake lithium extraction, seawater desalination and so on